Performing Manufacturing Operations: Best Practices for Mastering the Shop Floor

Every manufacturing company wants a lean operation with minimal waste and optimal productivity. The right methods and software can make it happen.

Every company in the production sector is looking for a better way of performing manufacturing operations. In this industry, you want to know how to increase efficiency, boost product quality, and maximize resources.

Manufacturing Operations Management (MOM) software has revolutionized the field with digital tools, especially since the dawn of Industry 4.0. Still, fancy software won’t automatically supercharge manufacturing operations. You must invest in the right tools and focus on the proper practices to ensure productivity.

We know how important efficiency and quality are to your business’s success. We’ve compiled a list of best practices for manufacturing operations and included information about how NetSuite software can help incorporate these practices into your processes.

SuiteDynamics partners with NetSuite to implement and customize NetSuite Enterprise Resource Planning systems and other products for clients who want streamlined operations and better productivity. Schedule a free consultation with our team today and eliminate redundancies and waste in your business.

What Is Manufacturing Operations Management?

Companies grow more adept at manufacturing operations with a robust MOM process. MOM oversees all aspects of production within a manufacturing facility to ensure efficiency, quality, and timely product delivery. It optimizes manufacturing, coordinating various activities such as:

- Production Planning

- Scheduling

- Inventory Management

- Quality Control

- Maintenance

- Resource Allocation

MOM streamlines operations and maximizes productivity while minimizing costs and waste. The process achieves this by implementing best practices and leveraging technology so manufacturers can improve performance, meet customer demands, and stay competitive.

MOM processes have recently improved with Industry 4.0, also known as “The Fourth Industrial Revolution.” This movement involves “smart manufacturing” and uses technologies that enhance real-time decision-making and transform how companies manufacture and distribute products.

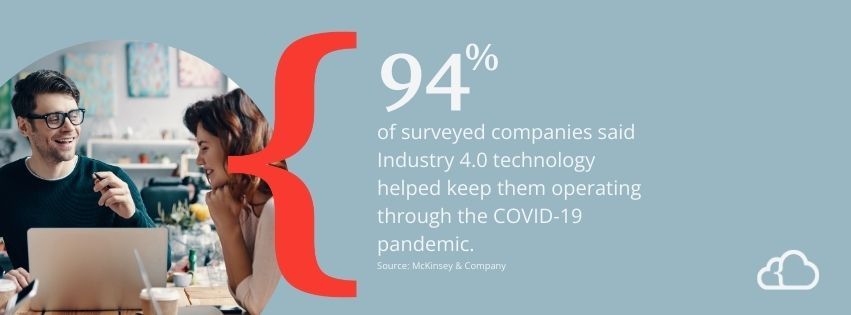

In a McKinsey survey of over 400 companies, 94% said Industry 4.0 technologies helped keep them running through the COVID-19 pandemic.

NetSuite for Manufacturing supports smart factories with a unified ERP platform that operates processes such as customer relationship management, inventory management, warehouse management, shop floor control, and supply and demand planning. And the system runs it all from one database.

Additionally, NetSuite offers multicurrency and multilanguage capabilities, so companies performing manufacturing operations in several countries can maintain a global business view. It also provides a real-time scheduling engine for complex finite and infinite capacity scheduling.

SuiteDynamics experts can explain NetSuite’s manufacturing features more thoroughly during your free consultation.

10 Best Practices for Performing Manufacturing Operations

The way you manage manufacturing operations will help ensure roaring success or dismal failure. The following best practices will help keep your shop floor efficient, productive, and thriving.

1. Embrace Lean Principles

The concept of lean production lies at the heart of manufacturing operations management. This approach to production minimizes resource consumption and maximizes value for the customer.

The lean method’s main principles—such as 5S (Sort, Straighten, Shine, Standardize, Sustain)—streamline operations and enhance productivity.

Doug Berger, president of Industry Reimagined 2030, writes in IndustryWeek that lean manufacturing can offer companies a nationwide productivity boost by changing the approach to production.

“Lean reduces the need for working capital, optimizes return on investment, and drives innovation,” Berger explains. “Companies create a culture of experimentation and learning. This encourages employees to think creatively and can lead to developing new technologies, products, and business models, driving growth and creating new markets for U.S. manufacturers.”

Additionally, Industry Reimagined 2030 reports that 95% of surveyed companies performing manufacturing operations with lean principles saw at least 20% productivity gains.

NetSuite ERP software includes several tools for implementing this method, such as advanced analytics and automation. These features help identify resource waste so your company can perform manufacturing operations more precisely and achieve better results.

Explore NetSuite tools more fully during your consultation with SuiteDynamics experts and discover how lean, efficient, and productive your factory can become.

2. Collect Solid Data

In the age of Industry 4.0, data is king. Collect accurate and comprehensive data about your manufacturing processes to make informed decisions and identify areas for improvement. Use sensors, RFID, IoT devices, and data analytics tools like NetSuite Analytics Warehouse to gather real-time data on production metrics, equipment performance, and quality standards.

3. Standardize KPI Tracking

Key Performance Indicators (KPIs), such as OEE (Overall Equipment Effectiveness), cycle time, or defect density, serve as vital benchmarks for measuring success while performing manufacturing operations.

Standardize KPI tracking processes to ensure consistency and alignment across all departments. Then, regularly monitor and analyze these indicators to gauge performance and drive improvement.

4. Automate

Embrace automation technologies that streamline repetitive tasks, reduce errors, and boost efficiency. Various types of automation, from robotic processes to inventory management systems, can significantly enhance productivity and free up valuable time for your workforce to focus on higher-value activities.

As time passes, these technologies only get better and save more money.

“A new generation of robots that are more flexible and versatile, and cost far less, than those used in many manufacturing environments today can be ‘trained’ by frontline staff to perform tasks previously thought to be too difficult for machines—tasks such as picking and packing irregularly spaced objects, and resolving wiring conflicts in large-scale projects in, for example, the aerospace industry,” a McKinsey article states. “Artificial intelligence is also making significant strides that are increasing the potential for automating work activities in many industries: in one recent test, for example, computers were able to read lips far more accurately than professionals.

According to Zipdo, an estimated 37% of the time employees spend in factories could be automated. Additionally, 85% of manufacturing executives expect artificial intelligence and automation to significantly impact their operations in the next five years.

Fortunately, automation is one of a NetSuite ERP system’s best features for performing manufacturing operations. The software automates several aspects of manufacturing, including invoice processing, allocation, order promising, orchestration and execution processes, and approval workflows.

You can see how the system reduces manual labor and error risks during your free consultation with SuiteDynamics experts.

5. Invest in Employee Training

Your shop floor is only as efficient as your team. Support employee training and development that advances staff skills and fosters a culture of continuous learning and improvement. The faster and better your team can work, the more productive and successful your business can become.

In 2019, Forbes published an article by Ryan Robinson stating that companies with staff training programs earn roughly 218% more per employee than businesses without formalized education.

“That's a pretty substantial lead, and training programs aren’t even the only way companies can foster a learning environment,” Robinson writes. “Regardless of the how, one thing is certain—leaders in the workplace have a responsibility to give their employees time for deep learning.”

Therefore, your company needs more than the right equipment and software to perform manufacturing operations. It requires staff members who can best use that equipment and software. Ensure your team has the technical training, ERP education, and soft skills development necessary to perform manufacturing operations best.

6. Prioritize Safety

Safety should always be a primary focus in any manufacturing environment because staff must be the company’s top priority. Robust safety protocols, proper training, and a safety-conscious work culture can prevent accidents and ensure employee well-being.

Of course, manufacturing accidents can have other consequences, such as:

- OSHA fines

- Equipment damage

- Floor closures

- Increased insurance costs

- Lost time

The U.S. Bureau of Labor Statistics reports that the private manufacturing industry had 373,300 recordable cases of nonfatal injuries and illnesses in 2020. Nearly 136,000 cases resulted in days away from work, 108,800 involved job transfer or restriction days, and 128,700 had other recordable cases.

Consequently, safety measures maintain staff health and morale but also help drive productivity.

7. Conduct Preventative Maintenance

A proactive approach to maintenance keeps equipment running smoothly and minimizes downtime while performing manufacturing operations. Schedule regular inspections, lubrication, and repairs to prevent unexpected breakdowns and extend your machinery’s lifespan.

You can also conduct predictive maintenance, which uses historical data to predict when equipment will break down so staff can minimize the time it’s out of service. This approach can increase company productivity significantly. According to McKinsey, it reduces equipment downtime by 30-50% and boosts machine life by 20-40%.

Staying ahead of maintenance issues will help your company avoid costly disruptions to your production schedule.

8. Prioritize Sustainability

The world has grown increasingly conscious of environmental impact, and “sustainability” has become more than just a buzzword. It's now a business imperative. For example, many companies performing manufacturing operations must comply with governmental regulations for environmental impact—or face penalties and legal problems.

Businesses must also focus on sustainable manufacturing to satisfy a green-leaning customer base. Many people want manufacturers to reduce waste and decrease their carbon footprints.

Customers also want more recyclable items. An Accenture survey reports that 83% of people said it was necessary or extremely important for companies to design products for recycling or reuse. More than half also said they would pay more for those products.

Ensure your company maximizes eco-friendly opportunities and implements energy-efficient manufacturing processes, waste reduction initiatives, renewable resource utilization, and more. Not only will your business reduce its environmental footprint, but it will also enhance the brand reputation and appeal to eco-conscious consumers.

9. Implement Quality Management

Just like safety, quality is non-negotiable when performing manufacturing operations. Implement robust quality management systems to ensure your products meet or exceed customer expectations.

Use stringent quality control measures and continuous monitoring and improvement initiatives to prioritize quality at every stage of the production process. This attention to detail helps maintain customer satisfaction and loyalty.

NetSuite Quality Management software helps ensure quality control. It establishes and automates standards, policies, and practices so your company can make the best possible products with the least overhead. The system offers:

- A mobile interface that allows quality engineers to perform inspections from the shop floor.

- Automated quality inspection triggers based on pre-established actions or conditions.

- Extensive volume analysis for raw data.

- And more!

Discover how effective quality management can become during a free consultation with SuiteDynamics experts. Our team will answer questions about the system and explain how it can keep your operations competitive and efficient.

10. Increase Visibility

Identify bottlenecks, optimize workflows, and improve decision-making by enhancing transparency and visibility while performing manufacturing operations.

Advanced manufacturing execution systems (MES) and data visualization tools offer the necessary visibility level to improve processes. The software provides real-time insights into production performance, inventory levels, and supply chain dynamics. Therefore, you can spot opportunities for optimization and drive efficiency throughout your organization.

NetSuite’s MES provides users with consistent access to real-time production updates. Its features include a barcode scanner interface and a user-configurable interactive tablet app so staff can record quality issues from the shop floor before they impact customers.

Explore the software with SuiteDynamics experts. We’ll show you the system’s top tools for ensuring company-wide visibility and optimal decision-making.

Turn Your Manufacturing Business Into an Efficiency Machine

Mastering manufacturing operations requires strategic planning, continuous improvement, and a commitment to excellence. You also need a robust software system to handle your company’s complexities and provide the necessary support to eliminate resource waste, increase data visibility, and boost product quality.

We want your company to become the best version of itself. SuiteDynamics experts will customize and implement NetSuite software that streamlines your manufacturing processes, maintains compliance, automates repetitive tasks, and more.

Contact our team today to discover an efficient and effective method of performing manufacturing operations.

We pull information from NetSuite material, SuiteDynamics experts, and other reliable sources to compose our blog posts and educational pieces. We ensure they are as accurate as possible at the time of writing. However, software evolves quickly, and although we work to maintain these posts, some details may fall out of date. Contact SuiteDynamics experts for the latest information on NetSuite ERP systems.

Part of this text was generated using GPT-3, OpenAI’s large-scale language-generation model. After generating the draft language, our team edited, revised, and fact-checked it to ensure readability and accuracy. SuiteDynamics is ultimately responsible for the content of this blog post.